What are the methods of yarn dyeing?

Yarn (including filament) dyeing has a history of nearly 1000 years, and hank dyeing has been used for a long time. It was not until 1882 that there was the first patent for cheese dyeing in the world, and then there was the warp dyeing.

1.hank yarn

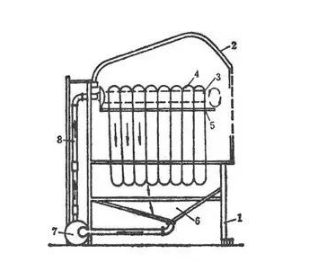

(1)normal temperature hank yarn dyeing machine

Hank dyeing is the process of converting staple yarn or filament into a hank yarn connected by frames on a spinning frame, and then dip dyed in various types of dyeing machines.

Yarn set on the perforated pipe, pumping dye solution from dyeing tank into the perforated pipe, spray on the yarn, suitable yarn dirty to the dyeing tank, at the same time, the rotary rod rotation to set on the perforated pipe Hank turn gradually, change and pipe contact position and achieve the goal of uneven dyeing.

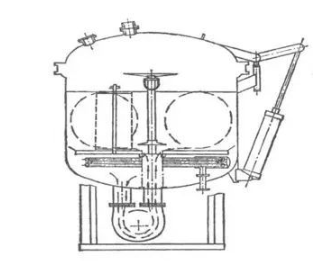

(2)high temperature hank yarn dyeing machine

During dyeing, the hank yarn is stacked in the yarn cage, the pressing plate is covered and tightened, and then the yarn cage frame is hoisted into the dyeing tank, and the dye liquor is added. Depending on the function of the pump, the dyeing liquid is sprayed through the yarn by the nozzle in the middle of the yarn cage, and then flows back from all sides, and then reverses and circulates after a certain period of time.

The high temperature and high pressure hank dyeing machine is mostly operated in a sealed way. The temperature rise and dyeing time can be automatically controlled, and the bath ratio is small. It is mainly used for dyeing polyester and its blended yarn, as well as other fibers, with good adaptability.

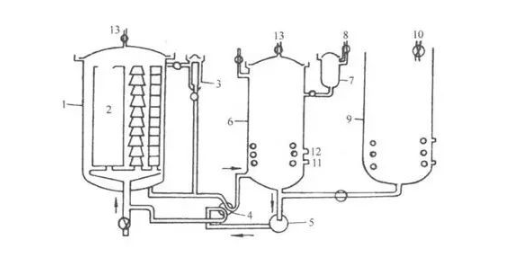

2.Cone yarn

Wrap the short fiber yarn or filament on the bobbin covered with holes (the winding density shall be appropriate and even, Generally referred to as "loose cylinder", it is then placed on the dyeing column (also called yarn bamboo, ingot pole, insertion rod, etc.) of the dyeing airborne yarn (also known as flat plate, hanging plate, yarn frame, etc.), and put it into the cylinder dyeing machine, and the dye liquid can penetrate the circulation ring between the bobbin yarn or fiber by the function of the main pump, so as to realize the dyeing by the bobbin dyeing.

Yarn winding on the hollow porous tube, the basic structure and yarn bobbin dyeing machine, high temperature and high pressure dyeing machine, the difference is really was bobbin bracket instead.

Contact:Xia Shaigen

Phone:86-13801428918

Tel:0086-523-84691028

Fax:0086-523-84691638

Add:No.88, Gongnong East Road, Jingjiang City, Jiangsu Province, China

蘇公網(wǎng)安備 32128202000145號(hào)

蘇公網(wǎng)安備 32128202000145號(hào)